SAP FIORI

Provides a modern, coherent user experience across your role-based apps.

In a perfect world, Enterprise Asset Management (EAM) for asset intensive industries like Utilities, Oil & Gas, Transportation, Pharmaceuticals, and Manufacturing would be straightforward.

The challenge is achieving current industry-standard maintenance operations while understanding how innovations may impact your operations.

We’ve been working with customers using SAP EAM in asset-intensive industries for over 18 years. Many of our customers experience pain from approaching maintenance as “firefighting” rather than prevention.

Frequently, those clients haven’t realized the ROI from a previous workforce automation project. Reasons include:

Provides a modern, coherent user experience across your role-based apps.

Provides a proactive service experience that boosts customer satisfaction. Streamlines processes for order scheduling and dispatch in a real-time environment.

Provides online and offline access to asset data, which helps you execute enterprise asset and service management processes quickly.

Intelligent asset management addresses issues that lower your return on assets and increase risks.

With Rizing-configured SAP maintenance management, you can cover the complete scope of work management. Rizing will review your maintenance execution processes, recommend improvements using modern SAP solutions, and demonstrate how complementary solutions from Rizing can improve your operations.

How is maintenance work generated?

How do you prioritize and prepare work packages and monitor order readiness?

How do you manage capacity, utilization, and optimization of resources?

How do we perform work quickly, correctly, and safely?

How can we improve strategies, costs, and equipment uptime?

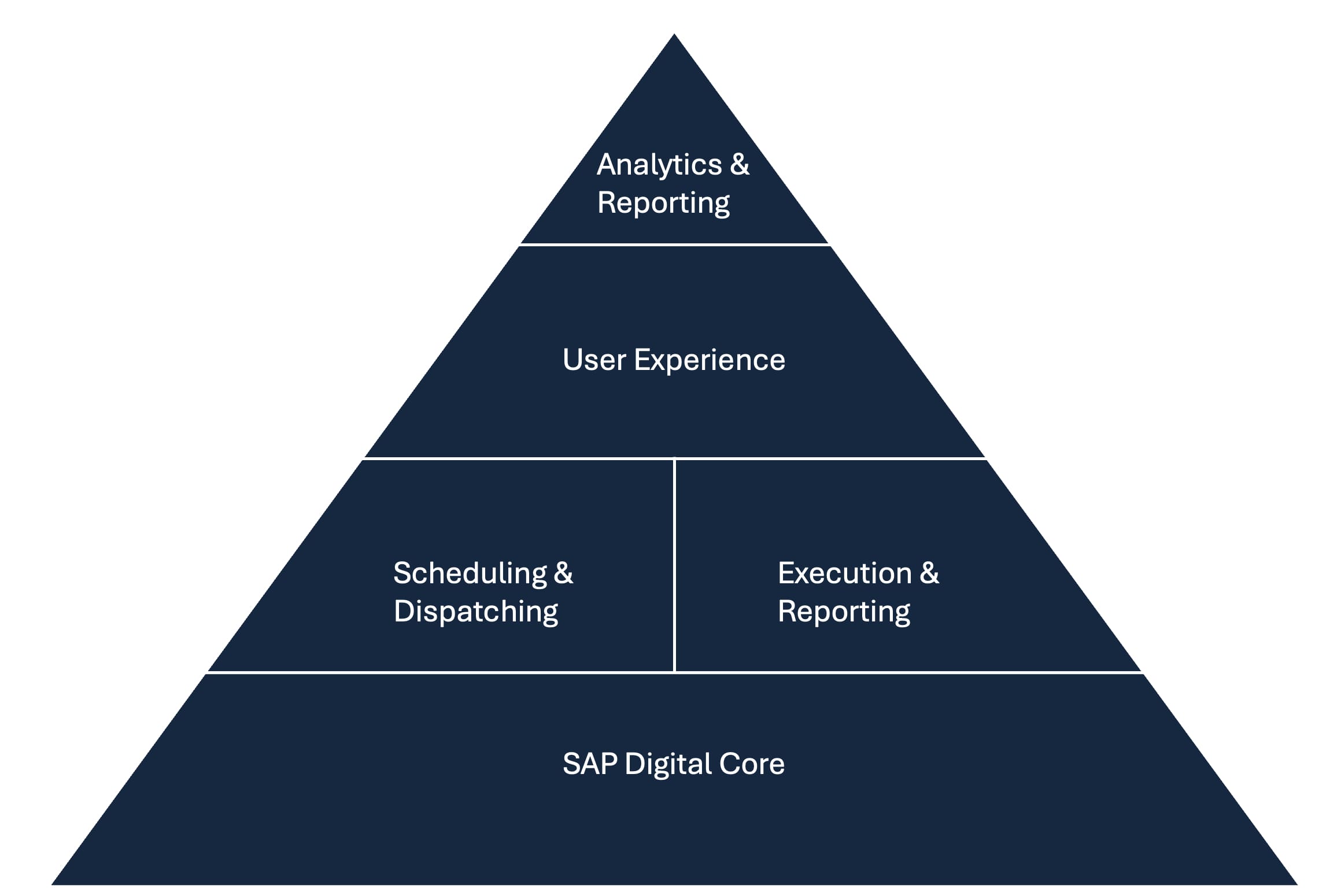

Maintenance management – scheduling, dispatching, execution, and reporting is a major part of the SAP digital core, whether your asset management processes run on SAP ERP (ECC) or SAP S/4HANA.

SAP EAM is now enhanced with applications deployed on SAP’s Business Transformation Platform (BTP) in the cloud, seamlessly integrating with the digital core.

BTP moves your core functionality forward with mobile applications, a simplified user experience, predictive analytics, workflows, integrations, and tailored solutions to benefit your unique business needs.

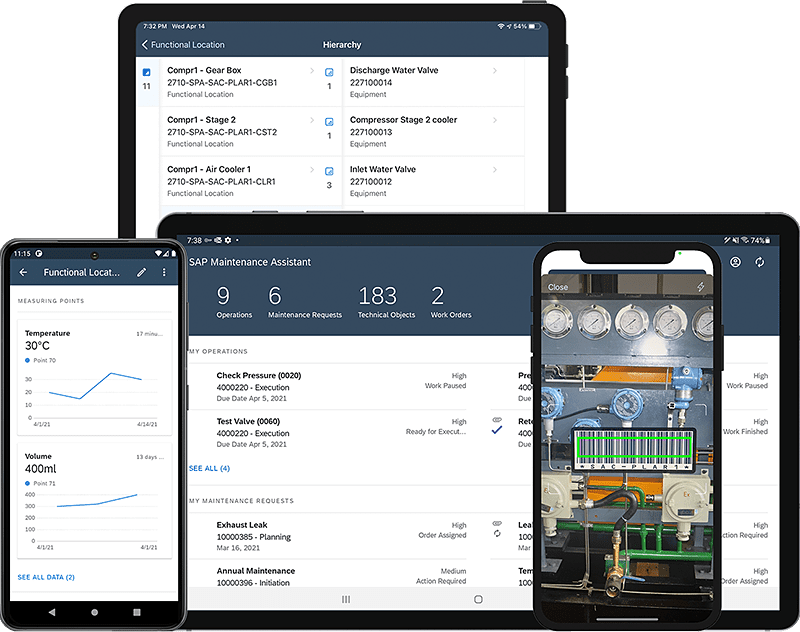

A better user experience helps your workforce be more successful.

SAP Fiori Apps included in SAP S/4HANA simplify resource scheduling, resulting in increased compliance, lower risk, and optimal asset performance.

Hydrogen is a cost-effective, device-agnostic solution with simple architecture, no middleware, quick time to value, and low support costs. Improve asset reliability and labor productivity with Hydrogen’s ability to:

Want to learn more about effective mobile maintenance execution, moving to SAP S/4HANA, or optimizing your SAP EAM practices? Contact Us – no ask is too big or too small!