Chapters in this Series:

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10

One of the most challenging aspects of maintaining assets that are spread across a large geographic area is maintaining an accurate and complete asset registry.

Field data collection challenges fall into two major categories:

- How do I accurately capture newly constructed or installed assets in the field?

- How do I identify and capture existing assets that are missing in my asset registry?

This article will show how to streamline the process of capturing new or existing assets in the field using LiDAR and other mobile tools to ensure a complete and accurate asset registry shared across an organizations SAP and GIS environments.

Constant Change

Asset management and inventory control is a dynamic venture. Components, equipment, location, and personnel are constantly changing.

Knowing the exact geographic location, operational status, and divisional responsibility of each asset can be a daunting task. However, an accurate and complete asset registry is foundational to the asset and maintenance lifecycle.

Get it right, and it may go unnoticed. Get it wrong, and your organization’s asset management and reporting process will be viewed negatively.

This can impact:

- Asset maintenance

- Analysis

- Safety

- Regulatory compliance

Risks of Field Surveys

A field survey is an effective way to collect new feature data. While on-site, crews can also confirm the current physical location and characteristics of the asset.

Field surveys are often completed by employees sent to the project area with a data collection device. Employees need experience to know what features are required and what attributes are necessary to complete the dataset.

A field survey is a risky, expensive, and time-consuming process. It exposes crews to the dangers of adverse weather conditions, distracted drivers and inquisitive or combative onlookers.

These dangers can cause crew members to capture only the bare minimum of data so they can leave as soon as possible.

The collected data is still valuable, but the limited effort keeps customers from getting more than what the original feature was for. Additional feature requests will require another field visit.

This can all leave organizations hesitant to do more field surveys.

However, there are ways to make process less painful.

LiDAR surveys and mobility tools can reduce field survey risks and pain points and make any trip to the field a chance to do a field survey.

LiDAR Field Data Collection

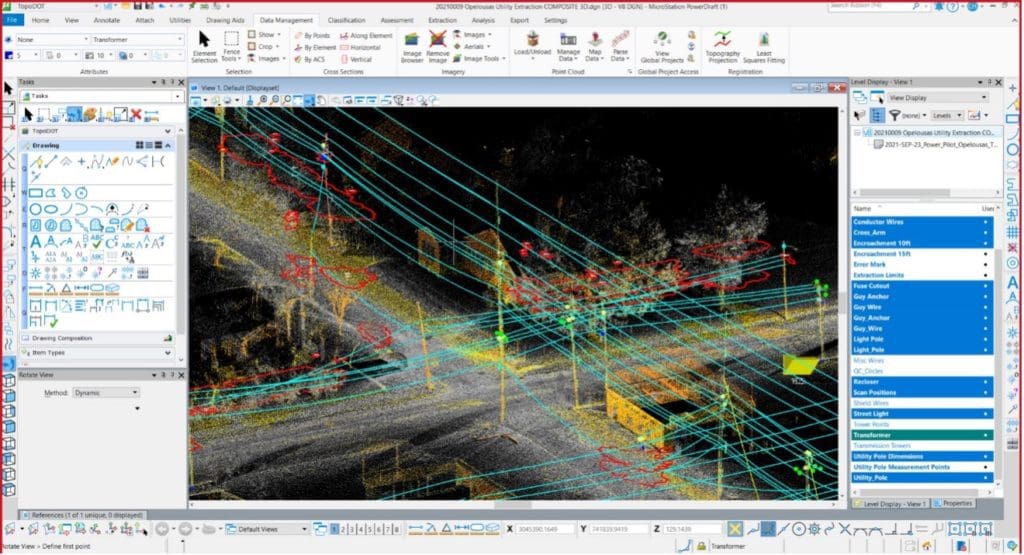

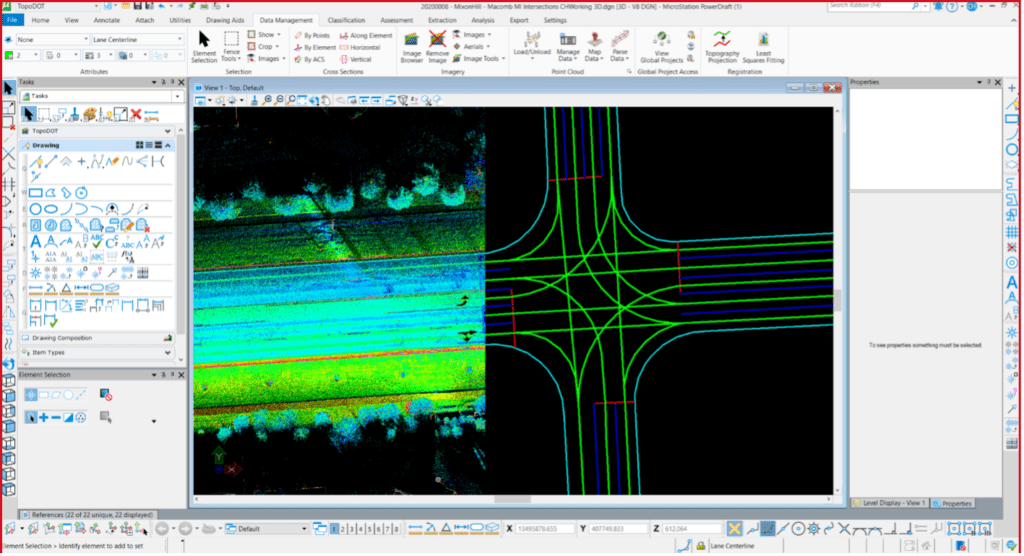

Using a Mobile Light Detection and Ranging (LiDAR) sensor package to collect 3-dimensional point clouds keeps field survey crews safe while also collecting more accurate data.

The Rizing Mobile LIDAR crew is a good example how this works. Our asset feature collection routine consists of a driver and a LiDAR collection technician who stay securely inside the vehicle while collecting geo-positioned 3D point clouds in a project area.

The 3D point cloud is a ‘line-of-sight’ collection routine where everything in a 360-degree field-of-view is precisely captured in its geographic position and scale. Data collection takes only as long as driving around the project area at speeds up to 50 mph.

Color Imagery

The Rizing Mobile LiDAR system also collects high resolution color imagery covering the entire 360-degree area of coverage as defined by the 3D point cloud. We include the georeferenced color imagery in our product deliverables. We also use it in the feature extraction and attribution phase of all projects.

Once the LiDAR crew confirms the field data collection, they can leave the project area and head back to the office. Working now in relative safety, analysts can extract features from the processed 3D point cloud and incorporate them into the database.

If the project evolves to require additional features or attribution, analysts can just go back to the saved 3D point cloud and add them.

Data Lifespan

The lifespan of the georeferenced LiDAR dataset, which has all the visible features from the collection area, is much longer than the minimum amount of data collected by a field survey.

Along with planimetric features such as poles, lines, conductors, attachment points, etc., being collected and attributed, the 3-dimensional component of the LiDAR data allows for:

- Topographic surface generation

- Pole “lean” angle determination

- Line sag and clearance

- Vegetation encroachment

- Tree and pole caliper, length, and distance measurements

- Post-collection design grade survey analysis

Rizing can deliver LiDAR generated and attributed design files usable with all geospatial mapping systems including AutoCAD, MicroStation and Esri.

We approach mapping projects by getting input from all stakeholders, then collaboratively designing a database.

Mobile Data Collection

Data collection can also be done with one person using a mobile device. It’s a less efficient process for large scale efforts, but for small scale or impromptu “catch-and-collect scenarios”, it’s an extremely efficient capability.

Mobile collections usually happen when a maintenance technician or inspector is out in the field and notices data that isn’t accounted for in the database. The technician captures the missing data on their mobile device and logs it for review and approval into the production asset registry.

Being able to update your system of record using an application that enforces standards while standing right in front of your asset goes a long way towards having accurate data.

We believe that so strongly, in fact, that we built a tool to do it.

Rizing Omnispatial

Rizing’s Omnispatial is an innovative web application used for field and office asset data collection and maintenance workflows.

Omnispatial works seamlessly with many published geospatial web services, including Esri map and feature services. It provides asset location for:

- Traditional map points

- Lines

- Polygon modeled assets

It allows data collection on linearly referenced features using Esri’s traditional linear referencing and R&H web services.

OmniSpatial works the same no matter if you are in the field or in the office. The app can work offline in areas with limited connectivity and then synchronize updates once a connection is available.

Summary

We’ve looked at two ways to collect asset data in the field.

Using LiDAR – and the accompanying video log – is an accurate and fast way to build complete datasets for large areas. Change detection allows organizations to find assets details that aren’t in the current database and add them.

Using Omnispatial and a mobile device, an employee can capture smaller changes or details missed by LiDAR.

Combined, these methods can quickly create an accurate and complete asset registry, especially compared to manual field survey or paper-based research project.